| Aracoat |

| Registration Date | 14 Apr 2018 |

| Revision Date | 14 Apr 2018 |

| Share |

Petroleum Pipeline

TiN/TiAlSiN Coating For Stainless SteelTitanium Nitride

TiN Nanostructure Coating CAS Number : 7440-31-5Titanium aluminium nitride

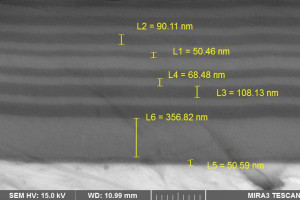

TiAlN Ultra-thin FilmCrack propagation resistance for intermediate nanolayers Life prolonging of coated parts Good adhesion of the coating to substrate in interface To avoid increase of residual stress and crack nucleation possibility in the coating, due to its thickness, the layers with nanometer thickness can be used. The residual stress of formed nanometric layers on the substrate, lower than higher thickness. In addition, multilayer nanometric layers control the micro-crack propagation in coating surface.

Applying a variety of nano-structured coatings with different thicknesses is capabilities of physical vapor deposition method (PVD). The services offered by Fanavaran Sakhtara company. For example, bilayer coatings TiN / TiAlN on steel substrate that has been done by the company is described in the following. It is about stainless steel coated with arc-PVD method, consist of sequential layers of TiN/TiAlN. The multilayer coatings usage is due to integration of the various coatings properties and coating properties optimization. The main advantages of hard coated tool based on titanium are high hardness, low friction coefficient and neutral behavior against abrasion and corrosion. These coatings have excellent properties in dry conditions and high cutting speeds. The TiN layer, as the first sticking layer to substrate, due to middle hardness, good adhesion and toughness is chosen. The last layer, TiAlN, due to the higher oxidation temperature (800 to 900 ° C) and good abrasion resistance in dry cutting operations, is used.