| Pak Shooma |

| Registration Date | 29 Sep 2018 |

| Revision Date | 29 Sep 2018 |

| Share |

Home Appliance Housecleaning

Dishwashing machineNanometric conservation coatings lead to better corrosion resistance. Accordingly, samples were scratched base on ASTM D1654-16 standard at first and then their corrosion resistance were evaluated by ASTM B117 – 16 “Standard practice for operating salt spray”. Salt spray testing is an accelerated corrosion test that produces a corrosive attack to coated samples in order to evaluate (mostly comparatively) the suitability of the coating for use as a protective finish. Mostly, the salt water contains 5%wt salt and 95%wt distilled water. PH of the solution is 6.5-7.2, spraying pressure is 0.83- 1.24 bar and the temperature of the exposure zone of the salt spray chamber is approximately 35 0C. According to ASTM B117 – 16 standards, coatings with the grade of 10 have the pest condition and 0 with the worst condition.

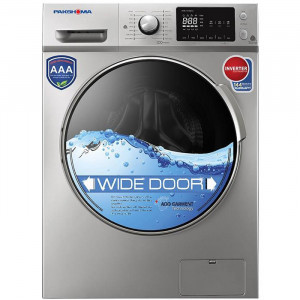

Washing machines are popular domestic appliances which as their name imply are used to wash clothes with water and detergents. There are different kinds of washings machines in the market with variety of applications. Front load washing machine is one of the most popular home kinds. Most of this home appliance have several washing programs and are easily adapted to kitchens because of their front doors. Due to their permanent exposure to detergents and water which may cause corrosion, they should be protected by some coatings such as conversion ones. Conversion coatings are coatings which their main application is corrosion protection and are produced with a chemical or electro-chemical process. Examples include chromate conversion coatings, phosphate and zirconium conversion coatings on steel, and anodizing. Among the conversion coatings, zirconium base coatings have advantages such as the absence of harmful elements such as nickel, chromium, phosphate, no environmental pollution, ideal corrosion resistance and better adhesion to the substrate. Generally these coatings can be used for appliances which expose to corrosive condition. Moreover, they have become interesting for decorative applications due to their beautiful color and used as an undercoat because of their special surface properties. On the other hand, conversion coatings have engineering applications due to their corrosion protection properties and decorative application due to their surface properties. Accordingly, these coatings can be suitable for some appliances like washing machines. Nano metric conservation coatings are used in this product to get better corrosion and adhesion properties.