| ARCHOIL |

| Registration Date | 28 Oct 2015 |

| Share |

Petroleum Oils and Lubricants Product Number : AR8300

Petroleum GreaseBoron nitride

BN Nanoparticle /Nanopowder CAS Number : 10043-11-5Tungsten disulfide

WS2 Nanoparticle /Nanopowder CAS Number : 12138-09-9Restores areas worn by friction Extends the life of components and bearings Eliminates corrosion Extremely low water washout at 0.50 Forms an ionic ceramic bond to the host alloy Reduces heat generation Non-toxic and readily biodegradable COF = 0.003 The extreme temperature of ceramic surface withstands 3500ºF Five times harder than the host metal Eliminate hydrogen embrittlement Restores efficiency Use on curved railroad track and wheels (double the life) The highest performance grease available Decrease of COF from 0.014 to 0.003 (4.5 times) Increase in the linear dimensions of parts (weight gain roller test rig at 0.03 grams) Reduction of linear wear from Ih=6.3x10 -8 = 2.3x10 -8 (3 times) Increase in critical loads from pcr=7.35 MPa to pcr 14.40 MPa (2 times)

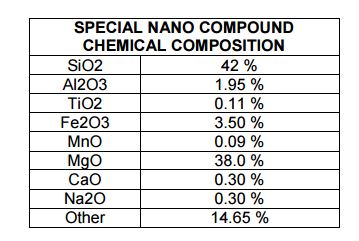

AR8300 contains a dozen nano synergistic elements, 10 years in developing, each mineral is chosen for its potential characteristics when reduced to the nanometer level. The base oil is the highest quality PAO Durasyn 148 selected for its extreme temperature capabilities. The thickener is fumed silica selected for high temperature operations. AR8300 restores worn surfaces in friction areas which is then 5 times stronger than the host metal. AR8300 stays active on the surface under heavy loads. AR8300 minerals interact with each other and the host metal creating a chemical reaction for the bonding and reconstructive process. AR8300 is for use in extreme environments such as heavy load bearings, curved rail tack, wind turbines, high performance, or wherever the present grease is over-challenged by the work load. Greasing intervals may be extended up to 3- 6 times or more. AR8300 by forming a new surface on the host metal eliminates corrosion, hydrogen embrittlement and micro-pitting. AR8300 coefficient of friction (COF) is a tribological breakthrough at 0.003, the lowest in Tribology.