| Insplorion AB |

| Registration Date | 3 Jul 2018 |

| Revision Date | 3 Jul 2018 |

| Share |

Automotive Auto Parts

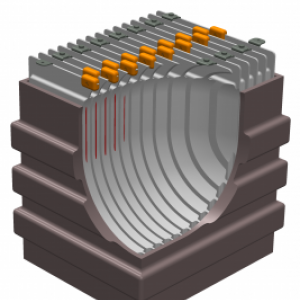

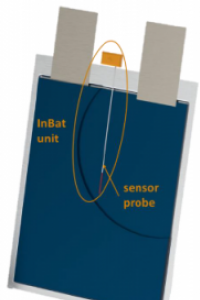

Battery sensor

The transition to renewable energy sources is necessary for the world to reach its climate goals. Here, batteries come in as an important part of the solution for especially two areas; vehicles and energy storage. Within both these areas, Insplorion’s sensor technique has great potential. With sensors measuring the charge within batteries on a molecular level, you can, by monitoring and controlling the batteries, achieve an increased energy availability, power density, charge rate and reduced risk for explosion, which all are important parameters for both vehicles and battery storage.

The demand for lithium-ion batteries, which is the main battery type, is expected to increase 6 to 7 times by 2026 compared to the levels of today, according to Benchmark Mineral Intelligence 2017 [1]. A rapidly growing and agile market means increased underlying demand and more possible collaborations, which benefits Insplorion.

Today, extensive investments in electric vehicles are made, but for electricity to become the main energy source for vehicles, more mileage, faster charge rate and lower price is needed. With Insplorion’s sensor technology, it is possible to get more effect out of the same batteries, which is beneficial on multiple levels, both price, weight, volume and environmental effects in the manufacturing process. This can bring batteries closer to the breaking point for when combustion engines no longer are economically and functionally motivated.

The increase in number of electric cars is immense. Bloomberg electric Vehicle Outlook 2017 [2] updated their one year old prognosis from 2016 [3] regarding the electric car chare of new car sales by 2040 from 35% to 54%. They also predicted that by then, 33 percent of all cars will be electric. They expect an inflection point between 2015 and 2030, where it really takes off, thanks to the fact that electric cars by then will be more economically viable than combustion engine cars, even without subsidies.

Renewable energy sources like solar and wind power are intermittent, and the effect supply doesn’t follow the demand. Therefore, it’s essential to find sustainable ways to store energy, to even out the energy supply over time. The characteristics of lithium-ion batteries are highly suitable for energy storage, but the price level still stands in the way of a broader use. This creates a great market situation for Insplorion’s battery sensor, which substantially reduces this problem. Since there is less demand for miniaturization and fewer regulations regarding battery storage than for electric vehicles, this area also fits well for an initial market penetration.

As a part of the EU project Adaptive Control of Energy Systems (ACES) Insplorion will participate in building four demonstrators for adaptive optimization of battery storage. Other collaborators are Fraunhofer IFF, Vänerenergi and ABB Power Grids. Insplorion are responsible for integrating the battery sensor in the battery storage system and optimize the signal- and control systems

Electric cars and energy storage are connected in several ways. For example, electrical vehicles need to run on renewable electricity to reach their full environmental advantage. Energy storage also benefits from the rapid battery development, accelerated by product development within the vehicle industry. There is, however an area where the mutual gains could be much more prominent than today, and that is the second life of vehicle batteries – a market almost non-existing, due to lack of measurability.

Today it’s hard to set a resale price of batteries, since it’s impossible to evaluate their status. It’s also difficult for the seller to give a warranty or, in the case of a warranty situation, establish the malfunction cause. This results in a non-existing secondary marked for batteries. Insplorion’s battery sensor provides a battery life history and a possibility to measure the battery capacity much more exactly, which makes it possible to set a price and give a warranty, which in turn lays the ground for a commercial secondary market for vehicle batteries.

Until now, no technology for measuring the State of Charge (SoC), State of Health (SoH) or inside temperature of commercial lithium-ion batteries has been available. Instead calculations are made based on voltage, current and outer temperature, which aren’t very reliable. The measurement uncertainty forces manufacturers and users to use over-dimensioned batteries. Due to the safety margins built into battery monitoring systems, the whole battery capacity can’t be utilized, which results in an ineffective use of the battery, a reduced life span, slower charging, increased safety risks, lack of information for second and third life use and poor use of nature’s resources.

By more effective monitoring and control, it is possible set the usage range of the battery closer to

its limits, and thereby get more out of the same battery. This entails some obvious benefits. With the same battery, a car can for example get more mileage and faster charge rate. Security is also increased, since the battery can be shut down faster, before an explosive situation occurs. Better control also results in a longer battery lifespan.

Measuring battery status inside lithium-ion cells with the help of our battery sensor results in up to 50% increase in available energy, up to 23% increase in charge rate [4] and up to 38% lower costs on pack level. Insplorion’s technology is currently available in commercially manufactured prototypes and also possible to miniaturize and mass produce at a cost level comparable to current battery systems.