| Oasmia Pharmaceutical AB |

| Registration Date | 10 Aug 2018 |

| Revision Date | 10 Aug 2018 |

| Share |

Medicine Pharmaceuticals

anticancer drugVitamin A

Nanoliposome

With approval from the Swedish Medical Products Agency and the US FDA, we manufacture drugs for both clinical sales and trials. Manufacturing approval requires the maintenance of cGMP (current Good Manufacturing Practice). GMP ensures that the patient is given drugs that are safe and of the right quality. The authorities carry out regular inspections to ensure cGMP.

Government inspections at our facilities have been successful, meaning the quality systems and processes are satisfactory and meet cGMP. On an ongoing basis, we at Oasmia are working to secure and improve the quality of our systems. Our production facility in Uppsala is designed to manufacture all of our company’s products on a small scale. Our facility can perform the chemical synthesis needed to develop our proprietary excipient XR17 as well as manufacture our suite of oncology products Apealea (Paclical), Paccal-Vet, Doxophos and Docecal.

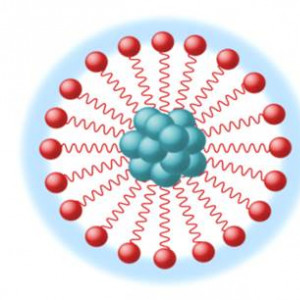

In order to supply the global pharmaceutical market with our oncology products for both human and veterinary use, a successful scaling up of the manufacturing process for Paclical and Paccal Vet has been initiated at Baxter Oncology GmbH in Germany. The manufacturing of XR17 is also being scaled up due to increased market demand. Manufacturing of our oncology products is done through mixing our patented and proprietary excipient XR17 with the active substance while the water solution of the product is prepared. In the water solution micelles are formed where the excipient encloses the active substance. The water solution is sterile filtered, filled in vials and freeze-dried. All manufacturing processes are carried out in premises classified as clean rooms, and are constantly monitored to secure the aseptic process and a product of high quality. All the labeling, storage and distribution of the finished products takes place in Uppsala.