| Lightlab Sweden AB |

| No Title | 0.03 MB |

| Registration Date | 18 Aug 2018 |

| Revision Date | 18 Aug 2018 |

| Share |

Construction Decoration

UV Light SourceSwitches on/off instantly – no warming-up time Low operating cost Higher bacterial effect than conventional UVC sources 100% mercury-free

Our UV Light Source, which was launched in autumn 2016, consists of a tubular UV lamp, a 10 W electronic driver and application software. The whole system is available for evaluation. Contact us if you are interested in trying out the product.

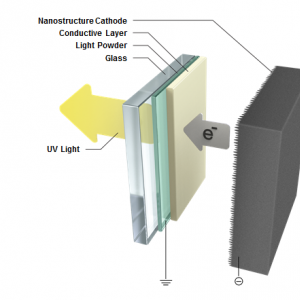

LightLab’s technology is based on two physical phenomena: field emission and cathode luminescence. Put simply, this means that light is created by generating an electron flow in a cold cathode. The electrons are emitted by the cathode and strike the inside of a lamp glass coated with light powder (luminescent layer) and a very thin layer of aluminium, creating light. The properties of the light, e.g. wavelength, are controlled entirely by the light powder. Red, yellow, green, blue and ultraviolet light can be generated in this way.

The secret behind this is a unique cathode with a patented structure of zinc oxide. Small, sharp nano-tips emit an electron flow when power is supplied.

The figure below shows the principle structure of a UV light source. On the far right is the cathode with the nanostructures, which send out (emit) electrons. The electrons pass through the conductive layer and reach the light-emitting material. The light that is generated then comes out through the glass.

LightLab’s bactericidal light source with 99.999999% reduction is totally free of toxic substances such as mercury.