| Parsa Polymer Sharif |

| No Title | 0.03 MB |

| Registration Date | 4 Oct 2018 |

| Revision Date | 4 Oct 2018 |

| Share |

Food Packaging

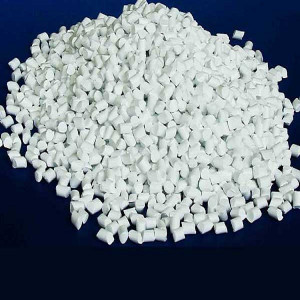

MasterbatchAdding nano-objects to the polymeric compounds result in improvement of their mechanical and chemical properties. Mechanical properties of the product are improved by standard strength test according to ASTM D637, so as the use of nanomaterials leads to a 9%, 7% and 23 % increase in yield Strength, fracture strength, and elastic modulus, respectively. A 10% and 6 % decrease in elongation in yield point and failure point also occurs, respectively. Relying on standard moisture absorption test according to ASTM E 104, a 200 % reduction in moisture absorption happens. By biodegradation test according to ISO 14855-2, the CO2 emission rate increases from 0.586 to 0.901 gr by adding nanofiller as well.

The petroleum resources are limited and the blooming use of non-biodegradable polymers has caused serious environmental problems. Thus, the polymer materials which are degradable and/or biodegradable have being paid more and more attention these days. Both synthetic polymers and natural polymers that contain hydrolytically or enzymatically labile bonds or groups are degradable. Synthetic polymers are quite expensive so the focus is on natural polymers these days, which are inherently biodegradable and can be promising candidates to meet different requirements. Among the natural polymers, starch is of interest. It is regenerated from carbon dioxide and water by photosynthesis in plants. Owing to its complete biodegradability, low cost, and renewability, starch is considered as a promising candidate for developing sustainable materials. compounding starch with Synthetic polymers can result in less use of synthetic polymers, but leads to decrease mechanical properties. Nanocomposites can display improvement in polymer properties such as mechanical strength, thermal stability, durability, chemical stability, flame retardancy, biodegradability, optical and electrical properties over neat polymers and conventional composites.