| Atrisa Industrial Complex |

| Registration Date | 1 Jan 2020 |

| Revision Date | 1 Jan 2020 |

| Share |

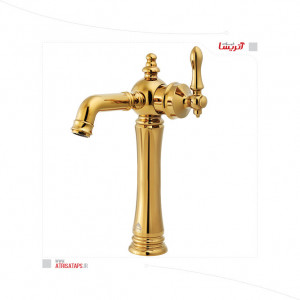

Construction Decoration

FaucetTitanium Nitride

TiN Nanostructure Coating CAS Number : 7440-31-5Nanometer thin nitride film of transition metals (TiN) Coating thickness less than 100 nm High hardness Suitable wear resistance Corrosion resistance Easy to clean High pressure and high temperature resistant ceramic cartridge Neoperl water consumption-reducing plotter

In addition to the type and the quality of the material used in fabrication of taps, other factors such as the geometry and the color of the used coating, is important. Generally, the taps are made of brass or lead alloys, and the applied coatings are the only parameter to make differences. The purposes of using the coating on the surface of the taps are improving the wear and corrosion resistance, as well as increased beauty. Color is the most important property of decorative coatings and TiN is the most well-known hard coat material. By coating TiN on a flat substrate, this attractive coating provides a high degree of hardness. This gold-plated finish has the ability to apply on the surfaces of valves made of different materials such as brass and Zamak alloys. In particular, since manufacturers always look for products with more beauty, quality and lifetime, nanostructured coatings are accepted to increase the hardness and corrosion resistance compared to thicker coatings. One of the common methods for applying nanostructured coatings is physical vapor deposition (PVD). This method provides the ability to create a thin layer with a thickness of less than 100 nm and provides a good adhesion and uniformity on the substrate..

The applied coating grain size and the thickness has been determined less than 100 nm. High hardness and wear resistance together with significant uniformity and adhesion of the coating to the substrate have been confirmed.