| Surface Sevin Pelasma Engineering |

| No Title | 0.05 MB |

| Registration Date | 6 Jan 2020 |

| Revision Date | 6 Jan 2020 |

| Share |

Others Other products

Hard CoatingTitanium Nitride

TiN Nanostructure Coating CAS Number : 7440-31-5Increment of hardness and abrasion resistance due to nanostructure coating Better resistance to crack propagations and toughness improvement due to nanolayer coatings Improvement of corrosion resistance and mechanical properties

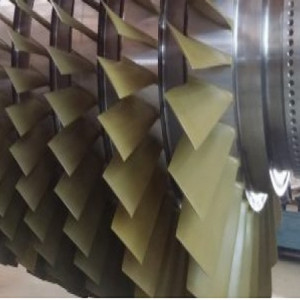

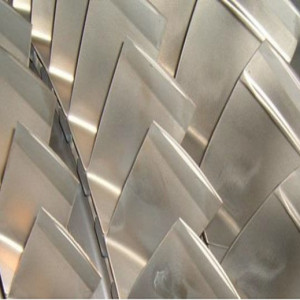

A compressor blade is part of a gas turbine and as the name suggests gas turbine engine compressors provide the compression part of the gas turbine engine thermodynamic cycle. A small proportion of the air enters the compressor where the air is compressed into a small volume with a corresponding rise in temperature, so this part exposed to erosive and corrosive conditions. In more aggressive conditions when particles such as dust are ingested to turbine compartment, these particles cause compressor damage, decrement of efficiency and also increment of the need for overhaul. Compressor blades are made of metal alloys and regarding to their applications need hard material coatings too. The presence of these hard coatings provides the erosion and corrosion resistance required for compressor. The most commonly coatings used are nitride coatings, including single layered TiN, ZrN, CrN, AlTiN, TiAlN; multilayered Cr/CrN, Ti/TiN and CrN/NbN. One of the common methods of applying hard coatings on the surface of the substrate is the Physical Vapor Deposition (PVD) method. Nanostructure and Nanolayer coatings were introduced when harsher condition from corrosion or erosion points of view arose. These coating were developed for better corrosion, erosion resistance and increment of coating hardness.