| BioSurfaces Inc. |

| Registration Date | 4 Feb 2020 |

| Revision Date | 4 Feb 2020 |

| Share |

Medicine Tissue Engineering

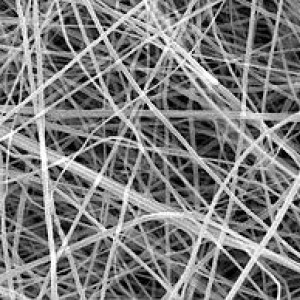

Drug loaded electrospun fiberEvaluation of our Bio-Spun™ materials, which were formed into artificial arteries, using specific staining techniques (histology) shows tissue integration and capillary formation after implantation, while the body walls off woven and knitted materials with a capsule of dense scar tissue. In the histology image of the industry standard below on the left, the empty spaces between the woven polyester fibers (white circles) and the stained tissue shows poor tissue integration. The yellow arrow shows the thickness of a blood clot which formed on the blood-contacting surface of the implanted woven artificial artery. In stark contrast, the image of our Bio-Spun™ artificial artery on the right shows new small arteries (capillaries) formed and complete tissue integration of the Bio-Spun™ material, such that the fibers are hardly discernible from the tissue. The green arrows point out a single layer of cells that has formed on the blood-contacting surface of the artificial artery, and the absence of a clot. The healing response to the structure of an electrospun material is a vast improvement over current implantable materials.

One of the core benefits of an electrospun polymeric (Bio-Spun™) materials is that it structurally mimics the natural biological scaffold onto which native human tissue grows, called extracellular matrix. This similarity to extracellular matrix encourages natural healing and tissue integration, even when using strong and biodurable electrospun polymers. This quality of healing is not achieved with woven and knitted biomaterials, which are the current industry standard.