| E-magy |

| Registration Date | 18 Jun 2022 |

| Revision Date | 18 Jun 2022 |

| Share |

Medicine Pharmaceuticals

Nanoporous silica

DEMAND FOR HIGH ENERGY BATTERIES IS ON THE RISE

With climate change a key issue in the world today, electrification of mobility is rising fast. The demand for battery power is growing, but standing in the way of wide scale EV adoption are restricted range, charging speed and cost. We believe our specialty silicon has the answers.

SILICON IS THE WAY FORWARD

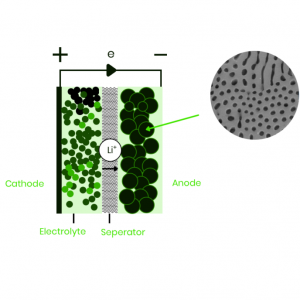

Today's Li-ion batteries use graphite as an active anode material, an approach which can not keep up with market demand. Silicon-dominant batteries are lower in cost and lighter - up to 50kg weight reduction per car battery pack, ready to power the next generation of EV batteries.

CHALLENGE: SILICON HAS UP TO 10X HIGHER CAPACITY BUT IS MORE LIKELY TO SWELL

Silicon has long been recognised as a promising active anode material due to its higher specific capacity than graphite. Until now, the transition to silicon was hindered because silicon swells and breaks when charged.

SOLUTION: NANO-POROUS SILICON

We invented a low-cost process to mass manufacture structured silicon particles that don't swell and break thanks to nanoscale pores. This unique specialty silicon is purpose-designed for silicon-dominant application in high performance Li-ion batteries.