| Haydale Graphene Industries Plc |

| Registration Date | 18 Jan 2023 |

| Revision Date | 18 Jan 2023 |

| Share |

Others Composites and Polymers

CompositeGraphene

C Graphene CAS Number : 7782-42-5

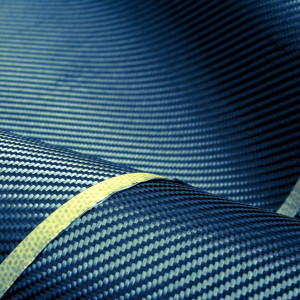

We have extensive experience in the design and manufacture of carbon fibre composites. By combining our HDPlas® functionalisation process with our expertise in graphene engineering and nano additive chemistry, we have developed a range of graphene-enhanced carbon fibre prepregs. We have created and tested multiple prepreg formulations that deliver enhanced mechanical, electrical and thermal properties.

These materials will be the basis on which we work with customers to develop cost effective, tailored carbon fibre composite prepregs for volume manufacture. This positions us strongly to service the composites tooling and specialist component markets.

We believe that this represents the next generation of carbon fibre prepregs, from which a range of materials with specific performance characteristics can be manufactured. By adding graphene nanomaterials, these prepregs will increase the impact resistance and compression after impact performance of carbon fibre reinforced epoxy components. Applications include aerospace, automotive, space and sports goods such as bike frames and racing boats.

Haydale’s electrically enhanced prepreg has been specifically designed to enhance the electrical conductivity of the laminate.

This prepreg material delivers a new generation of carbon fibre-reinforced composites having improved electrical conductivity. These materials can be used for structural components as well as for enclosures for the electronic avionics systems.

The materials developed have potential applications with regards to UAVs (drones) along with commercial aviation in general, and space applications. This technology has additional applications with regards to wind turbine blades, particularly in offshore locations which are susceptible to lightning strike.

An electrically conductive masterbatch is also commercially available and the Haydale team has been working with customers to test the capability, achieving significant results over existing materials.

The enhanced resin provides improved performance for use in:

Lightning strike

Edge glow

Electrical screening