| Lockheed Martin Corporation |

| Registration Date | 16 Oct 2023 |

| Revision Date | 16 Oct 2023 |

| Share |

Environment Water and Wastewater

Water MembraneGraphene

C Graphene CAS Number : 7782-42-5

Since the ancient Egyptians first filtered water through sand, man has used screens and filters for everything from large-scale industrial processes to brewing beverages to delicate medical procedures.

Today, filtration and separation process are all around us, in almost every industry in some form, and the need for improved performance and efficiency is greater than ever. New technologies are opening new frontiers.

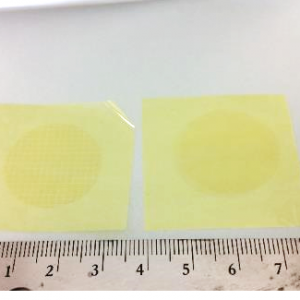

Lockheed Martin is making revolutionary breakthroughs with its graphene composite membrane technology. The active layer of our membranes is an atomically thin layer of perforated graphene, which puts the theoretical limits of membrane performance within reach. Graphene membranes feature many of the benefits of standard track etched separation membranes, but at several times their permeability permeability because of graphene’s thinness. No membrane can be thinner than an atom. But can something so thin be practical in the real world? Yes. Our membranes can withstand 100’s of psi of trans-membrane pressure, can tolerate high radii of curvature, are highly flexible, and device fabrication processes can be performed by skilled technicians using hand tools outside of a clean room environment. Also, our membranes are probably more affordable than you think.

Our membranes are graphene composite membranes, consist of a perforated graphene layer combined with a highly porous substrate. We can tailor the properties of the substrate via functionalization and other means to give the resulting graphene composite membrane a wide variety of properties.

Other groups around the world have published on large area graphene and roll-to-roll processes. How perfect is that graphene? Graphene for separation membranes requires an extremely low defect rate at the nanoscale. Even nanoscopic defects can be leaks for some separation applications. We have achieved the degree of quality to make graphene-based separation membranes a reality at functional scale. Because of this quality, unperforated versions of our membrane can make effective impermeable barriers.