| Nanostone Water |

| Registration Date | 29 Sep 2015 |

| Share |

Environment Water and Wastewater

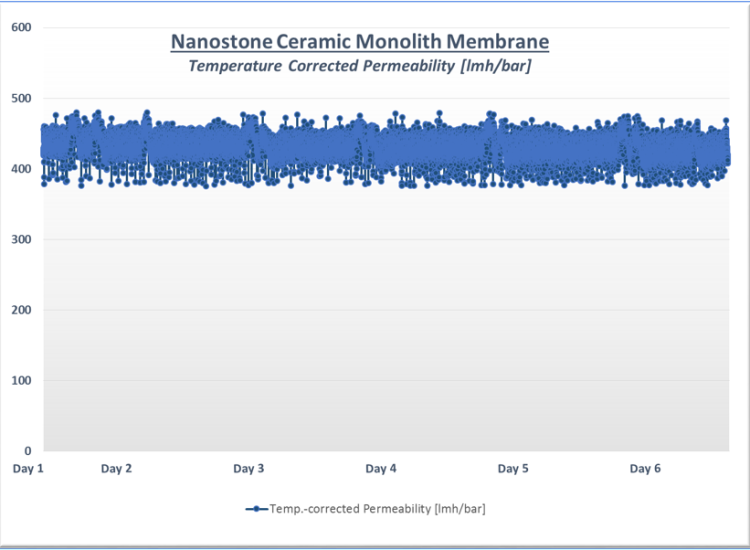

Water MembraneThis following data was acquired at a European pilot site with feedwater iron levels of 0.5 to 1.0 mg/L and turbidity ranging from 8 to 12 NTU. A ceramic monolith module with a nominal pore size of 100 nm consistently produced permeate quality < 0.01 mg/L iron and turbidity of < 0.1 NTU. A stable filtration flux of 400 lmh (236 GFD) was observed with a 98% recovery rate. The expected comparable filtration flux for most polymeric hollow fiber membranes operated under the same conditions is ~ 85 lmh (50 GFD). Under these conditions, Nanostone’s ceramic membrane demonstrated an apparent flux advantage 4.7 times that of polymerics. For more in-depth updates of our pilot site progress, please subscribe to our Newsletter.

Ceramic MF/UF membranes have been applied in industrial fluid and water treatment applications since the early 1990’s. These early membranes were produced in tubular and flat sheet configurations with significantly lower surface area compared to polymeric membranes. The high cost of these membranes have limited their application to the most challenging applications where polymeric membranes are known to fail. In recent years, high surface area ceramic membranes have become available, but at 4-5 times the cost of polymer membranes.

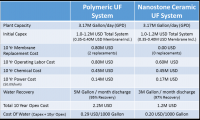

Based on the pilot data gathered from various sites over the past year a techno-economic model was developed to estimate the 10 year operating cost and cost of water for a 3 MGD (500m3/hr) industrial waste water reuse plant using UF/MF membranes designed to treat effluent from an existing conventional biological treatment system. The model assumes a 10+ year life for the ceramic membranes and a 4 year life for the polymeric membranes. Overall the, ceramic membrane system saves $1 Million in operating cost over 10 years and results in a >30% cost of water savings compared to the polymeric membrane model. In addition there is a 2 million gallon savings of water every month with the higher water recovery rate which can mean substantially more savings. When the capital expense is the same and you save the cost of buying two sets of replacement polymeric membranes as well as a substantial amount of water savings the Nanostone Ceramic advantage is crystal clear.

The most common ceramic membrane in use today is a multi-channel tubular configuration designed for “inside-out” operation with feed channels between 2 and 8 millimeters. These membranes are often run in cross-flow mode to minimize accumulation of solids. These tubular membranes are physically robust but have a relatively low surface area density contributing to higher applied costs. The higher cost has generally limited their application to aggressive temperature and chemical conditions where polymeric membranes are known to fail.