| NanoWorld |

| Registration Date | 13 Mar 2016 |

| Share |

Electronics Sensor Product Number : PPP-NCLPt-50

Afm TipChromium

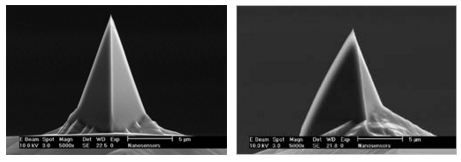

Cr Nanostructure Coating CAS Number : 7440-47-3metallic conductivity radius of curvature better than 25 nm tip height 10 - 15 µm high mechanical Q-factor for high sensitivity alignment grooves on backside of silicon holder chip precise alignment of the cantilever position (within +/- 2 µm) when used with the Alignment Chip compatible with PointProbe® Plus XY-Alignment Series

The new PointProbe® Plus (PPP) combines the well-known features of the proven PointProbe® series such as high application versatility and compatibility with most commercial SPMs with a more reproducible tip radius as well as a more defined tip shape. The minimized variation in tip shape provides more reproducible images.NANOSENSORS™ PPP-NCL probes are designed for non-contact mode or tapping mode AFM (also known as: attractive or dynamic mode). As an alternative to NANOSENSORS™ high frequency non contact type (NCH) the NCL type is offered. This type is recommended if the feedback loop of the microscope does not accept high frequencies (400 kHz) or if the detection system needs a minimum cantilever length > 125 µm. Compared to the high frequency non-contact type NCH the maximum scanning speed is slightly reduced. This sensor type combines high operation stability with outstanding sensitivity and fast scanning ability.The PtIr5 coating is an approximately 25 nm thick double layer of chromium and platinum iridium5 on both sides of the cantilever. The tip side coating enhances the conductivity of the tip and allows electrical contacts. The detector side coating enhances the reflectivity of the laser beam by a factor of about 2 and prevents light from interfering within the cantilever. The coating process is optimized for stress compensation and wear resistance. The bending of the cantilever due to stress is less than 3.5% of the cantilever length.Please note: Wear at the tip can occur if operating in contact-, friction- or force modulation mode.