Applications

Lack of fluorinated components

Reduction of chromium anhydride concentration in electrolyte by 30-35%

Reduction of electrolyte outflow with technological satellites and vent emission by 45-55%

Application of additional foam generating agents and mist extractors is not required thanks to a small size of gas electrode products beads and electrolyte mirror surface tension

Compliance with electrolytes, not containing fluorides

NCM Chrome coatings are suitable to all brands of carbon and stainless steel, copper and copper alloys, wrought aluminum alloys and high-silicon aluminum alloys as well as different brands of cast iron. NCM Chrome electrolytes have a minimum pickling ability, if applied to items like copper, copper alloys, aluminum and aluminum alloys. It allows precision processing over such items. During the chroming process, electrolytes are minimally deteriorated by metal details and jigs ions.

NCM Chrome electrolyte possesses minimum environmental hazard generalized criterion, if compared with other electrolytes, applied for chroming, requires low amounts of water for flushing and is characterized by low main component outflow.

Current efficiency at high current density is at 23.5-25%. Voltage during electrolysis varies from 3.9V to 6.8V, depending on the current density, temperature, hydrodynamic mode, type of items, the location in their electroplating bath, anodes condition and the reliability of electric contacts.

Electrolyte recirculation and electrochemical regeneration is available

NCM Chrome chromium coating is the most economically viable. NCM Chrome coating requires minimum power consumption for temperature mode stabilization.

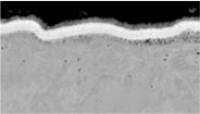

Essential characteristics of one-layered, two-layered, three-layered and superfine NCM Chrome coatings are provided at temperature modes from 40°С to 70°С. Steady and unsteady current loads from 10 A/dm2 to 100 A/dm2 and hydrodynamic mode. In case of electrolyte flow, chroming at higher current density is available.

NCM Chrome application provides the most favorable conditions for anodes long-term exploitation, because of the lack of lead chromate complex forming at the surface of lead anodes and application of 4-8% of stannic and stibium. Application of wear-resistant titanium-based membrane anodes is available.

CrO3 content in electrolyte does not exceed 170g/l + various modifications of NCM Chrome additives.

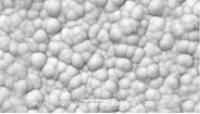

NCM Chrome chromium coating technology has been successfully applied in Russia, China and Taiwan in such spheres as multifunctional chromium coating of vehicle rods, hydraulic cylinder elements, flow compartments of oil pumps, die molds for various kinds of plastic, various details for textile industry, crystallization vats for continuous steel casting machines, oversized gate valves and other special equipment within 3 years. Nanostructured fine NCM Chrome coatings under 1 µm for polished stainless steel possesses unique decorative and wear-resistant properties which can be applied for modern design and finishing constructions of various dimensions for interior and exterior.

Properties

Chemical Stability

Thermal stability

Corrosion resistance

Wear Resistance

Hardness

Manufacturer's Description

is a high efficiency method of hard, wear-resistant and corrosion-resistant decorative chroming without fluoride applications with high current efficiency. It allows for creation of glossy, hard, wear-resistant and corrosion-resistant chromium coatings by means of variation of current, temperature and hydrodynamic modes, coating thickness and modifying additive contents.