| Shafigh Industrial Group |

| No Title | 0.02 MB |

| Registration Date | 1 Jan 2020 |

| Revision Date | 1 Jan 2020 |

| Share |

Construction Structural Materials

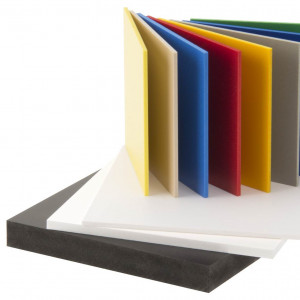

PVC Foam BoardHigh density (0.52 g/cm3) Length: 2440 mm (Can be changed according to customer order) Width: 1220 mm (Can be changed according to customer order) Thickness: 3-30 mm Cheap, light, and easy to install Can be substituted with conventional structural materials such as wood, plaster, cement, concrete and clay Anti-humidity and waterproof Anti-shock Resistant to chemical agents such as salts, fats Resistant to fire (direct heat of 70 ° C - indirect heat 100 ° C) Soundproof Anti-Dust, Antibacterial

Nowadays, light structural panels play a significant role in industrial production and development of buildings. PVS foam panels named as PVC sheets are one of these panels. PVC foam plates or PVC sheets are a commonly used plastic with a chemical compound consist of polyvinyl chloride. They are widely used in furniture, buildings and advertisement industries and can easily compete with wood and clay. These foam sheets are extremely resistant to moisture and corrosion. Foamed sheets are also lightweight and highly resistant to chemicals. The plates can be engraved, embossed, printed, colored and laminated according to user requirements. On the other hand, there is a possibility of punching, sawing and screwing these sheets without any crack. PVC wall coverings are often made as double-glazed and laminated form that can protect the wall against heat and sound. In some cases, these wall coverings come in solid form, which increases its endurance and does not require chassis. The foamed sheet does not decay over time and its color remains still sharp and clear.

In order to improve the PVC properties, various materials are used such as fillers including silica nanoparticles (SiO2) (to increase strength and profile strength), lubricants (for ease of producing of profiles and decreasing of surface roughness), and thermal stabilizers for example zinc oxide particles (To enhance the thermal resistance and color stability against ultraviolet radiation).

By using the nano-zised additives, the hardness (indicative of resistance to deformation) and fastening ability (in terms of the force needed to remove the screw) of the sample containing nanoparticles showed an improvement of 32% and 24%, respectively, compared to the as received sample. Also, An negligible improvement of about 4% is observed in the color stability.