| FreeVolt USA, Inc |

| Registration Date | 19 Jul 2023 |

| Revision Date | 19 Jul 2023 |

| Share |

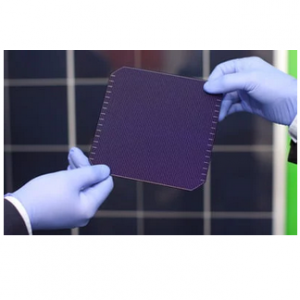

Renewable Energies Solar Cells

Solar CellGraphene

C Graphene CAS Number : 7782-42-5

The biggest ongoing challenges for manufacturers of photovoltaic (PV) modules are loss of efficiency, limited vitality, and a drop in the conversion from kilowatt peak (kWp) to actual kilowatt hours (kWh).

Photovoltaic Graphene Matrix Technology or “PV Graph” shatters the mold of traditional BUS BAR PV technology and will soon become the go-to technology for Solar Power Installations.

PV Graph utilizes a hybrid cell technology – combining thin film tech with crystalline silicon tech – to produce 50% higher efficiency modules that last longer, are less prone to micro-damage, and even when damaged, still work with almost zero loss of productivity.

PV Graph is theoretically compatible with every known standard crystalline cell across the world, but because of its revolutionary design feature, it not only operates at peak efficiency, it does so with lower manufacturing costs, both realized and environmental, and opens the door for even more savings in the production stage.

Traditional PV modules are made up of a group of silicon cells connected to each other in series, much like old fashioned Christmas lights. Therefore, the loss caused by any damage, even micro cracks, in each individual cell was multiplied through the system. Similarly, at dawn and dusk, some cells being in shadow (diffused light) results in losses that traditional BUS BAR technology cannot accommodate. That’s not even taking into account the standard 3-5% loss in energy conversion.

PV Graph solves many of these problems. The modified architecture of their photo array means that there is 1:1 kWp to kWh conversion – 100% of the solar energy captured by the PV module is transferred into usable electrical energy. The graphene matrix responds significantly better to both scattered and low light. And even when some cells are in deep shadow, it doesn’t affect the sensitivity of the rest of the active module, as it does in traditional BUS BAR technology.

Plus, their lower temperature manufacturing process means there is less inadvertent damage at the production and installation stages – no more high heat soldering means less thermal stress and fewer instances of silicon cells cracking. That means a longer life for the modules, again, saving significantly on on-going production costs.

FreeVolt™ is a vertically integrated enterprise which concentrates only on one goal – saving energy. Their latest release is the next step, not only for their company, but for solar panel technology across the globe. PV Graph will soon be the standard by which future PV modules are judged.