| Natural Nano |

| No Title | 2.01 MB |

| Registration Date | 12 Jan 2018 |

| Revision Date | 12 Jan 2018 |

| Share |

Others Composites and Polymers

CompositeClay

Al2O3 • 2SiO2 • 2H2O Nanotube CAS Number : 1332-58-7NaturalNano’s patent product bypasses these multiple processing steps and complex chemistry by offering the manufacturer a turnkey drop-in solution that runs on standard conventional equipment. Pleximer is a turnkey concentrate in the form of pellets that can be added directly into the extruder by the end manufacturer. Pleximer contains Halloysite clay nanotubes, shown below, that are blended with a specific polymer base utilizing NaturalNano’s patent technology. The resulting product is a drop-in additive. Pleximer doesn’t require the expensive exfoliation process needed by platy clay systems, and it successfully provides the required dispersion in a polymer matrix. Platy nanoclays, by comparison, have trouble achieving uniform dispersion, even with exfoliation, and work with a limited number of polymer families. The nanocomposite market is also limited by the small number of manufacturers that have invested in the know-how and the specialized equipment necessary to run platy nanoclays. NaturalNano believes that the Pleximer technology will have rapid industry acceptance because it enables manufacturers to produce nanocomposites with existing equipment. NaturalNano is currently focused on leveraging this new drop-in, turnkey advantage to a select number of industrial compounders who supply major industries such as automotive, performance sporting goods and aerospace.

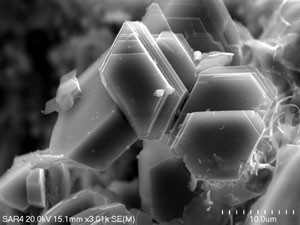

Today, most nanocomposites used in the plastics industry are made with “platy nanoclay” materials, but these clays are very difficult and expensive to process. Platy clays, such as the Kaolin clay below, contain layered two-dimensional sheets held together by an intercalation (or intermediary) layer. The sheets must first be exfoliated, or chemically separated, so they can function as nanoparticulate fillers and be dispersed in the polymer matrix. In today’s platy nanoclay production process, these multiple steps lead to complexity, cost, and dispersion quality challenges. In addition, most manufacturers do not have the specialized equipment needed to produce composites with platy nanoclays – this required investment is the biggest market barrier for nanoclays.